HB-Therm®

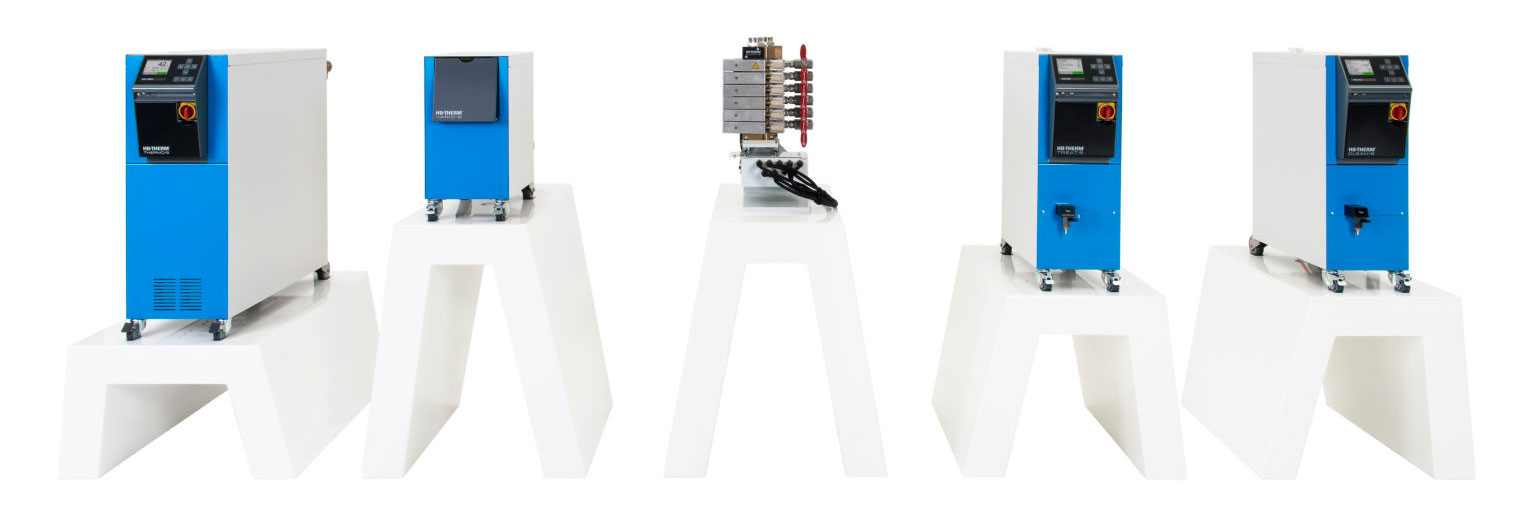

THERMOREGULATORY METERS 5

Thermo-5 devices are characterized by efficient and reliable operation and are used in temperature control of injection molding tools or similar processes.

Advantages

- High precision temperature control

• ± 0.1 Kelvin with automatic optimization contro

• Temperature, pressure, and flow calibration

• Assured inspection quality - Shorter heating and cooling time

• Tankless system heats up only the amount of power needed - Lower energy use in heating and cooling

• Minimum internal volume of circulation requires less energy

• Intelligent cooling concept reduces losses - Easy operation

• Intuitive navigation in 21 languages

• Precise instructions at the push of a button

- Fully automatic process monitoring

• Constant monitoring of temperature, flow and pressure

• High-precision flow measurement with ultrasound

• Detect hose breaks and leaks

• Pump status monitoring - Pump with energy efficiency concept

• Eco-pump, energy saving through speed control - Additional functions

• Automatic cooling and depressurization on shutdown

• Recording data via USB and export to Excel

• Recording of mold data

• Possibility of control via injector

VARIO UNIT 5

Alternatively, it connects the hot or cold unit to the same circuit and offers easy and quiet operation.

- Applications for:

• Eliminate weld lines

• Precision in contour molding with thin structures

• Excellent surface quality

• Reduction of high injection pressures

Advantages

- Durable enclosure

• Non-corrosive materials only in the hydraulic circuit

• Change without pressure shocks

• Enhanced mold protection

• Oxygen contactless closed system

• Prevents steam, flaking and corrosion

- Intelligent operation determines set-point temperatures, delays and switching times

• Freely selectable control mode

• Convenient functions

• USB data recording and Excel analysis

• No pressure shocks

• No compressed air

Treat-5 UNIT

HB Therm Treat 51

Inadequate water in the temperature control circuit promotes fouling and corrosion, thereby increasing maintenance costs and at the risk of premature failures.

The risk increases for water temperatures above 140 ° C, rotating passages or small cross sections of the channel. The Treat-5 provides temperature control units with water defined quality system.

It provides easy and environmentally friendly operation. After initially adding the conditioning agent, it works automatically and warns the user periodically for verification.

Advantages

- Performance

• Perfect heat transfer between medium and mold

• Precise temperature control

• So that channels remain clean - Prevents the consequences of poor water quality

• No blocked circuits

• Reduces faults, wear, and maintenance to a minimum

• Longer mold life - Efficient operation

• Reduced water and agent consumption by reusing system water

• The pump works only if necessary - Simple operation

• Well-organized menus in 21 languages

• Intuitive navigation

• On-site instructions at the push of a button

- Safety

• Interactive user orientation

• Automatic filling level monitoring

• Periodic warning to check water quality - Light display

• Easily readable with high contrast

• Free choice of display windows and values - Convenient functions

• Calculates the exact amount of agent required

• Easy instructions for monitoring system water quality

• Integrated logbook accompanies the treatment process

• Easy front sampling

• USB data recording and Excel analysis

FLOW FLOW METER 5

Flow-5 external flow meter monitors parallel circuits individually and immediately detects any changes before the quality of the produced products can be compromised.

- Features wide range of application:

• Flow measurement from 0.4l/min

• High temperature up to 200°C

• Different configurations

• Continuous flow and temperature monitoring by circuit

• USB data recording

• Calculates the exact amount of agent required

• Easy instructions to monitor system water quality

• Integrated logbook accompanies the treatment process

• Easy frontal sampling

• Usb data recording and Excel analysis

Advantages

- Fully automated process monitoring

• Continuous flow and temperature monitoring per circuit

• Highly accurate ultrasonic flow rate measurement - Simple operation

• Manual flow adjustment wizard

• Convenient functions - Improved mold protection

• Early detection saves expensive maintenance

- Process power determination by circuit

• Automatic threshold value setting

• USB data recording and Excel analysis - Durable construction

• Only non-corrosive materials in the hydraulic circuit

• Flow rate measurement without any moving parts

CLEAN-5 CLEANING UNIT

Clean-5 removes corrosion and impurities from channels from molds, thermoregulators and hoses. Provides additional protection for mold storage for long periods. It helps theuserto add the chemicalagentsand continue their operation automatically.

Advantages

- Main points:

• Cleaning of mold cooling channels

• Automatic flow reversal

• Pressure sensor to detect cleaning level

• Clean, rinse and conserve

• Neutralizes cleaning solution before disposal - Easy Operation

• Interactive user orientation

• No agent clutter

• Well-organized menus in 21 languages

• Intuitive navigation

• On-site instructions at the push of a button - Sustainable

• Neutralizes cleaner before draining

- Useful functions

• Calculates the exact amounts of agents required

• The integrated logbook accompanies the cleaning process

• Easy front sampling

• USB data recording and Excel analysis - Light display

• Easily readable with high contrast

• Free choice of display windows and values - Durable cabinet

• non-corrosive materials only in the hydraulic circuit

• Unsealed stainless steel pump

• Ultrasonic fill level measurement with medium separation